Read before choosing 14x14x2mm carbide inserts

A 14x14x2mm carbide insert refers to a specific type and size of carbide insert commonly used in machining operations. Here's some information about a 14x14x2mm carbide insert:

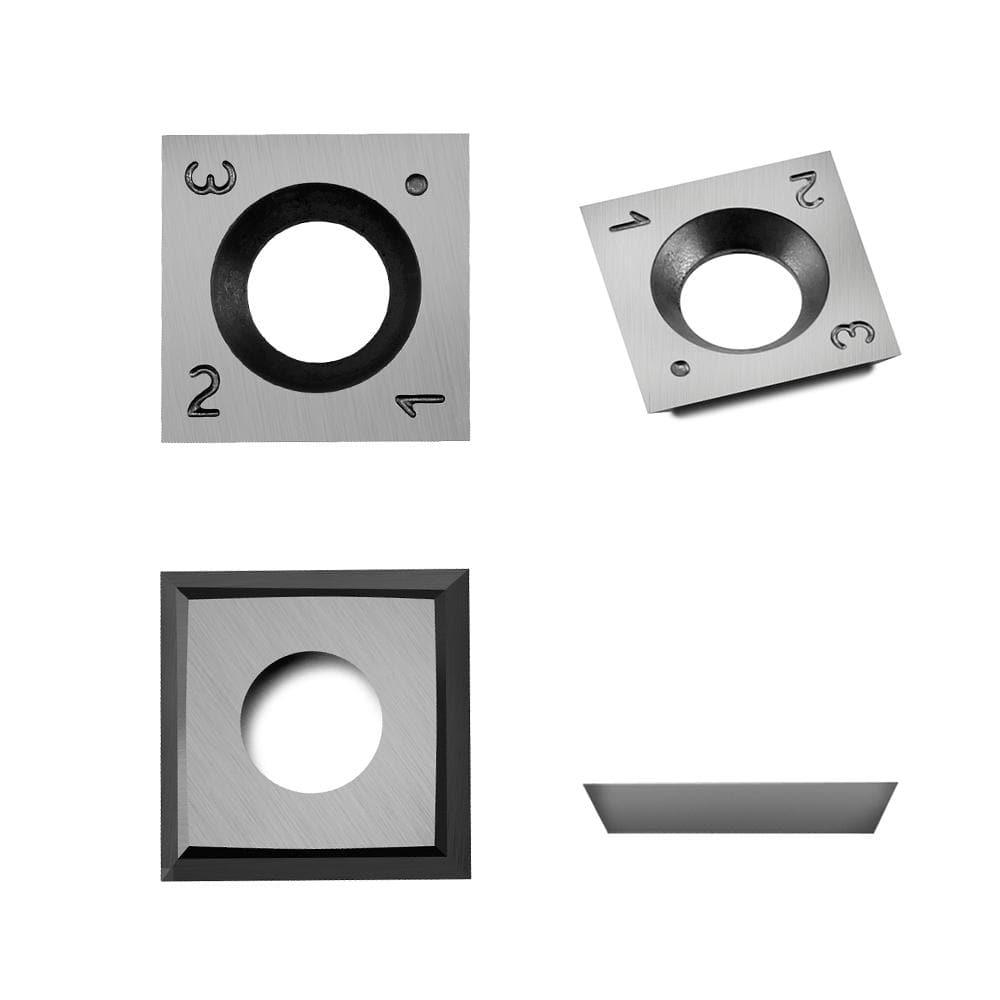

Size: The dimensions "14x14x2mm" indicate the length, width, and thickness of the carbide insert. In this case, the insert is square-shaped with sides measuring 14mm in length and width, and it has a thickness of 2mm.

Material: Carbide inserts are made from a hard and durable material called cemented carbide or tungsten carbide. These inserts consist of a carbide tip or cutting edge that is brazed or clamped onto a steel or carbide body. Carbide inserts are known for their excellent wear resistance and ability to withstand high cutting temperatures.

Application: Carbide inserts are commonly used in various machining operations, such as turning, milling, and drilling. They are widely used in the metalworking industry for cutting and shaping workpieces made of different materials, including steel, cast iron, stainless steel, and non-ferrous metals. The specific application of a 14x14x2mm carbide insert depends on the type of machining operation and the material being machined.

Advantages: Carbide inserts offer several advantages over traditional high-speed steel (HSS) cutting tools. Some of the key advantages include:

1. Wear Resistance: Carbide inserts have superior wear resistance compared to HSS tools. The hard carbide tip can withstand high cutting speeds and maintain its sharpness for longer periods, resulting in extended tool life and reduced downtime for tool changes.

2. High Cutting Speeds: Carbide inserts can handle higher cutting speeds, allowing for faster material removal rates and increased productivity.

3. Heat Resistance: Carbide inserts can withstand high cutting temperatures without losing their hardness or cutting performance. This makes them suitable for demanding machining operations that generate significant heat, such as high-speed machining or roughing applications.

4. Versatility: Carbide inserts are available in various geometries, coatings, and chipbreaker designs, allowing for customization based on specific machining requirements. This versatility enables optimized cutting performance for different materials and applications.

Disadvantages: While carbide inserts offer many advantages, there are a few considerations to keep in mind:

1. Cost: Carbide inserts tend to be more expensive than HSS tools, primarily due to the higher cost of the carbide material. However, their longer tool life and increased productivity often justify the upfront investment.

2. Brittle Nature: Carbide inserts are more brittle compared to HSS tools. They are susceptible to chipping or breakage if subjected to excessive force or impact, especially in interrupted cutting or unfavorable machining conditions.

3. Initial Setup: Using carbide inserts requires proper setup and alignment to achieve optimal cutting performance. This includes ensuring correct insert orientation, proper clamping, and appropriate cutting parameters.

It's important to note that the specific design, geometry, and coating of a carbide insert can vary depending on the manufacturer and intended application. Therefore, it's essential to consult the manufacturer's documentation or the insert's technical specifications for precise information about a particular 14x14x2mm carbide insert.